|

Menu Code: LOC Inventory -> Control |

Locations describe where items are stored and picked from in a Warehouse. You have a wide degree of flexibility when setting up your locations, they could be a trunk for a field support technician, a staging area, a warehouse, or a portion of a warehouse; such as a shelf or a bin.

Locations can be flagged as MultiItem and Pickable by checking the associated checkbox. You should check the MultiItem checkbox if you you intend to stock more than one item in that location. The Pickable checkbox must be checked to make items in the location available to Pick Tickets. The calculation for available inventory quantity also only includes items in Pickable locations.

Location Types determine the intended purpose of the location. For example, stock locations are intended to store inventory while receiving locations are used to stage items during the Receiving process. Every location must be assigned a type.

Foura is pre-configured with the following Location Types:

| Type | Description |

|---|---|

| STOCK | Stock - locations used to store items that are available to fulfill orders. These locations are normally Pickable. |

| RECV | Receiving - staging locations for items while they are being received and inspected, or are waiting to be put-away in a stock location. |

| HOLD | Hold - location intended to set items aside for a while until some issue is resolved. These locations are normally NOT Pickable. |

| WIP | Work-in-process - staging locations intended for items that have been pulled from stock for use in a manufacuring/assembly process. These location should NOT be Pickable. |

| RES | Reserved - staging locations for items that should only be used for a specific customer or purpose. |

The list of Types can be edited by selecting the LocType list on the Possible Values form.

Location Zones identify different logical areas in your warehouse. For example, you might need to separate inventory for Refrigerated, Hazardous Materials, Bulk items, High-Dollar, etc. A location can only be part of one Zone.

The list of Zones can be edited by selecting the LocZone list on the Possible Values form.

If you have a lot of locations then you will need to use a numbering system to organize them. A good numbering system will make it easy to locate any item in the warehouse. This saves you time and money.

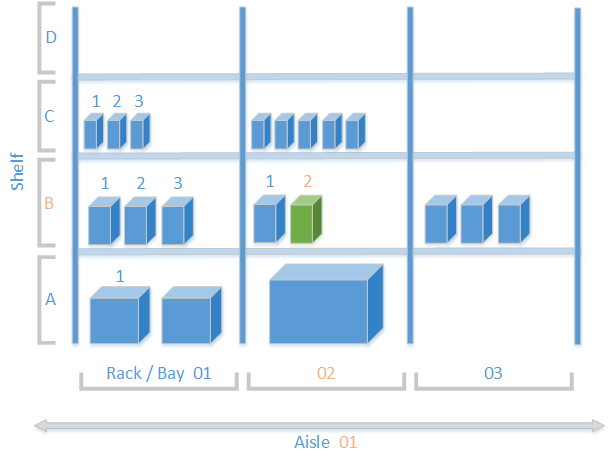

Locations numbers should be organized into segments, from the largest to the smallest as follows:

If your warehouse is smaller then only use the minimum number of segments required to describe your locations. When assiging values for each segment you can choose to use numbers (01-99) or letters (A-Z). In general if there are more than 7 or 8 possibilities then numbers will work better. For most people it is faster to determine that 13 comes before 16 than it is for them to figure out whether M comes before P! You should include dashes between each segment for readability.

Here is an example of how you might number locations in one aisle of your warehouse:

|

Note: The location with the green box is: Aisle 01, Rack 02, Shelf B, Position 2 01-02-B2

|

The following default roles can use this form:

| Role | Allowed Actions |

|---|---|

| rl_User | View |

| rl_StockControl | View and Edit |